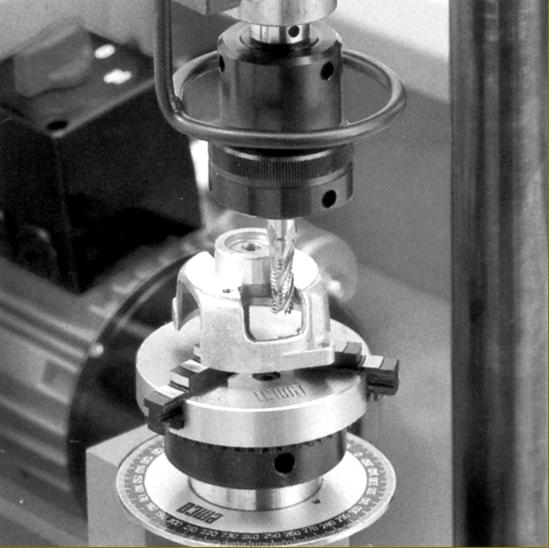

B14 Screwing the tensioning tube into the clamping cylinder. B9 Machine without clamping cylinder with bore. B9 Machine with clamping cylinder with bore. B8 Connection values for tensioning tubes. A15ī Description and operation Reference points. A12 Electrical connection - Machines with Fanuc-Control. A10 Electrical connection - Machines with Sinumerik 810D/840D. A10 Additional criteria for installation. A8 Machine with gantry loader and chip conveyor. A7 Machine with bar loader and chip conveyor. A6 Installation plan, dimensions of the machine. B13 Position of tensioning tube by changing clamping devices. B12 Position of tensioning tube during the change of clamping devices.

B12 Machine with clamping cylinder without bore. B12 Machine with clamping cylinder with bore. B11 Connection values for tensioning tubes.

10 Technical data of the machine - metric. 9 Warranty conditions for new EMCO machines. , Hallein/Taxach - AustriaĬontents Adequate Use. All rights reserved, duplication only upon authorization of Messrs.

#Emco compact 5 cnc simulator manual#

Abteilung Technische Dokumentation A-5400 HALLEIN, AustriaĮC conformity The CE sign certifies together with the EC declaration of conformity that the machine and the manual correspond to the EC guideline for machines 89/392/ EEC and its modifications 91/368/EEC and 93/68/EEC. For any inquiries or proposals for improvement with a view to the present operating instructions please get directly in touch with EMCO MAIER Gesellschaft m. Your machine will ofer you, on the other hand, permanent operatability and long live. We therefore ask all machine operators to read the subject user's manual prior to start-up and also at a later point of time and to observe the guidlines attending it as exactly as possible. The present user's manual for the EMCOTURN 365 comprises the description of the machine and the accessories, instructions and procedures for handling and realization of cleaning and maintenance work by the user as well as stipulations to be observed for the prevention of accidents and machine damage. One of our more than 100 general representatives worldwide will inform you on particular new developments and their retrofitting possibilities.

Immediately available service engineers, telephone service as well as a 100 % spare part supply exceeding the 10-year obligatory provision is something natural for us. Due to the worldwide industrial use of our machines we dispose of a service network which covers all world areas. Due to various accessories and special equipment such as integrated swivelling loader, bar feed and loading magazine, tool holder, tool fracture control and an external measurement station still a higher degree of automation can be achieved. Due to an optimum distribution of machining sequences high production flexibility, half processing time and, thus, double productivity are achieved. Our experience over decades and new customer requirements led to the development and the construction of the EMCOTURN 365 lathe for complete machining from blank to components ready for installation. Introduction For more than five decades EMCO has been developing wood and metal working machines and has been successfully on the market since 1980 with computer controlled machine tools and systems for industry and training. Machine Description Emcoturn 365 Ref.-No. Emcoturn 365 Modular CNC-Turning Center for Complete Machining

0 kommentar(er)

0 kommentar(er)